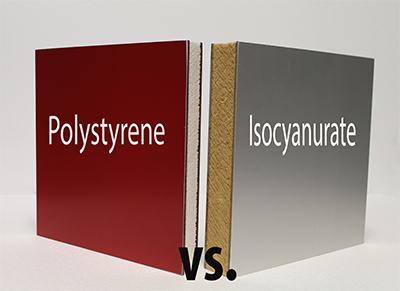

Polystyrene vs. Polyisocyanurate

The primary difference between the 2 core materials is the insulating value (or R-Value). Polystyrene has a typical R-value of approximately 4.4 per 1″ thickness of material. Polyisocyanurate’s typical R-value for the same 1″ of material is approximately 6.0.

When laminated into a 1″ thick panel with standard 1/8″ substrates and aluminum skins, the polystyrene panel yields a total R-value of approximately 4.7 while the Polyisocyanurate panel will achieve an R-value of 6.4. In comparison, a typical 1″ insulated glass unit offers an approximate R-value of 2.4.

So if you’re looking for the most economical core material, choose Polystyrene. If you need more insulating value, you’ll want Polyisocyanurate. As previously mentioned, either core will give you a quality product.