Polystyrene Panels: A High-Performing Solution for Construction

Innovations in the construction industry continue to merge economic efficiency and materials with building owners’ changing needs and desires.

Using new technology and tried-and-true materials like infill panels with a polystyrene core from Mapes streamlines the construction process so that builders can work more efficiently, save money and still deliver the quality that make the buildings aesthetically pleasing, energy-efficient and cost-effective to build.

What Are Infill Panels With a Polystyrene Core?

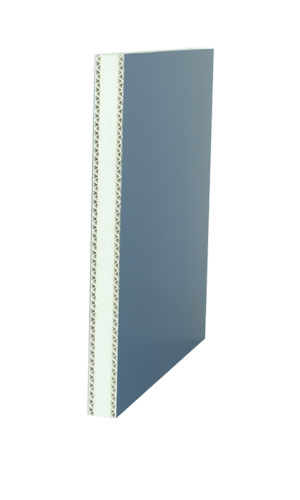

Infill panels with a polystyrene core are one of the products that builders are using to build better and faster without compromising quality.

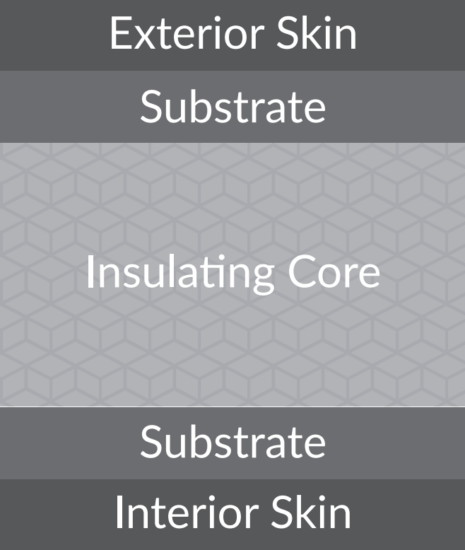

They are durable, energy-efficient and made from environmentally friendly materials. While these panels can be made with as few as three layers or as many as eight layers, the most common type uses five layers.

Polystyrene-Core Infill Panels: The Five-Layer Design

Five-layer polystyrene infill panels consist of an outer aluminum skin and an insulated polystyrene core covered with a stronger material like tempered hardboard, plastic, cement board or gypsum.

The layers of the infill panel give it strength, and the polystyrene at the core insulates the entire panel. Not all panels have polystyrene cores, but the material is one of the most popular in the industry.

Expanded Polystyrene Panels

Expanded polystyrene (EPS) panels are made from lightweight plastic foam — which is made from polymerized styrene monomers.

Steam is applied to cause the material to expand into “beads.” This material is then molded by compression and heat to form rigid sheets. EPS panels are available in various types and thicknesses, each designed for specific purposes.

Most builders use EPS panels because their performance is comparable to XPS panels, but the cost is lower. The only real difference in performance occurs when building below-grade.

High-quality manufacturers, like Mapes, can even custom-make EPS panels to fit the design’s aesthetic while also providing the insulation needed for large spandrel areas.

The Benefits Of Polystyrene-Core Infill Panels

Infill panels with a polystyrene core are the most popular choice for new commercial construction due to their cost-effectiveness, sustainability, energy efficiency and extreme weather resistance.

Cost Effectiveness

Polystyrene-core infill panels are builders’ first choice because they are the most cost-effective option. The panels themselves are priced well for the elevated aesthetics and increased thermal rating they provide. Buildings constructed with these infill panels also have a great insulation value.

The infill panels block sunlight and increase R values, which makes them good insulation in a glazing system. In a larger commercial space, having an infill panel in a glazing system results in significant energy savings.

When it comes to installation, these infill panels can further decrease builder costs. Because of their lightweight composition, polystyrene-core infill panels are easy to work with. They speed up installation and are easier to move to the job site — this can save on labor and transportation expenses.

Energy-Efficiency

Due to their insulating properties, polystyrene-core infill panels are highly energy-efficient. Polystyrene has low thermal conductivity, so heat transfer is minimized, and indoor temperatures are kept stable in all weather conditions.

Minimal Heat Transfer

Polystyrene is a thermal insulator that minimizes heat transfer through walls, floors and ceilings. The low thermal conductivity of these infill panels helps maintain consistent indoor temperatures without artificial heating or cooling.

This can reduce energy bills and greenhouse gas emissions and improve the comfort of a building’s occupants. Polystyrene’s insulation properties also stay stable for a long time, making the infill panels a wise long-term investment.

Moisture Resistance

Moisture resistance is crucial in construction, and polystyrene-core infill panels excel at this. Polystyrene’s closed-cell structure — where each cell is sealed off from its neighbors — stops water from infiltrating and contributes to its thermal insulation.

Preventing water absorption mitigates the risk of rot, mold and mildew, keeping indoor air quality healthy for occupants. Polystyrene’s moisture resistance also contributes to structural integrity and makes these panels suitable for exterior applications such as insulation for below-grade foundations.

Find Your Perfect Paneling Solution Today

Mapes is proud to support the best architects and builders by offering innovative building products that transform the industry. For over 70 years, builders, architects and industry pros have chosen Mapes products.

Find our products near you or contact us directly for a custom quote or spec for your next project.