Insulated Panels: A Guide to Better R-Value

Infill panels in a curtain wall serve several roles in a building’s overall performance — insulation being a major one. The insulated panels’ thermal resistance, also known as the R-value, will directly impact the building’s energy efficiency and the associated heating and cooling costs.

Because energy efficiency can affect the space’s longevity, comfort, marketability and productivity, choosing insulated panels with the best R-value is essential.

Understanding R-value and discovering what’s available with insulated infill panels will allow you to select the most energy-efficient solution for your next project.

What is R-Value?

The R-value of an insulated panel is the thermal resistance of that material — it measures how well a material resists the flow of heat. Insulated panels with a higher R-value have better thermal efficiency and less heat transfer.

The formula that’s used to determine the R-value of an insulated material is:

R-value = Thickness of material / Thermal conductivity (also called the K-value)

A higher R-value means that a material has better insulation performance, meaning the material will resist heat transfer more effectively.

Understanding Thermal Resistance

Heat naturally flows from warmer areas to cooler areas. If you’re trying to keep heat inside a building in winter or outside during summer, you want materials with high thermal resistance to minimize this flow.

Materials that have low thermal conductivity like foam or fiberglass have a high R-value because they resist the flow of heat. Thick materials, or layered materials, also have a high R-value because they block heat from transferring out.

How R-Value Affects Energy Efficiency

When architects are designing buildings, they look for building materials that are going to have the best durability and energy efficiency over time. Insulated infill panels have a high R-value, allowing for stable and comfortable temperatures.

By resisting heat transfer, insulated panels reduce the need for heating and cooling, leading to lower energy consumption. This is especially important for large buildings where energy costs can be significant.

Buildings with better thermal performance are more energy-efficient, helping reduce carbon footprints and meet the requirements of green building initiatives. Some insulated infill panels are designed to meet environmental standards like LEED.

Types of Insulated Panels and Their R-Value

Insulated infill panels’ thermal resistance plays a critical role in regulating the internal temperature of the building and contributing to energy efficiency.

Insulated infill panels made from insulated metal, glass, concrete or EPS all have different R-values because the materials they’re made from have different thermal resistance properties. The R-value of the panel depends on the material’s thickness and its thermal conductivity:

- Insulated Metal Panels: These can have R-values ranging from R-2 to R-6 per inch of thickness, depending on the type of insulation used in the core. Panels can be made up to 6 inches thick, offering an R-value of 40 or higher.

- Glass Panels: Standard glass panels have low thermal resistance, typically around R-1 to R-2. However, modern low-emissivity (Low-E) glass can improve thermal performance.

Materials with higher R-values like EPS have a low amount of heat transfer so they are almost always the best choice for commercial building projects. Materials with lower R-values like glass are not as effective at maintaining a comfortable temperature and can increase heating and cooling costs.

Comparing Mapes-R, Mapes-R+ and Other Panels

At Mapes, our insulated sandwich panels are an energy-efficient, cost-effective alternative to insulated glass, Low E Glass and other glazing options for new builds. Curtain wall, window infill and spandrel panel projects can be designed to provide optimal insulation and aesthetic appearance.

To meet the energy design requirements of various projects, we can produce insulated panels in any thickness between ½ inch and 6 inches. The overall thickness of the panel is determined by the thickness of the insulation used in the panel’s core. The thicker the insulation, the higher the R-value.

The types of insulation we use for our panels are:

- Polyisocyanurate: This offers the highest R-value, with a 1-inch panel achieving an approximate R-value of 6.4.

- Polystyrene: This is our most common insulation type due to its lower price and high R-value. A 1-inch panel achieves an approximate R-value of 4.6.

- Micore: This solution is typically used when a non-combustible product is required (NFPA 285). A 1-inch panel achieves an approximate R-value of 2.5

Here’s a better look at our panels compared to standard glass and brick panel options.

Mapes-R Panels

With an R-value of up to 40, Mapes-R panels offer various solutions to improve the thermal efficiency of window, spandrel, curtain wall and glazing applications.

Mapes-R panels can be manufactured to match any architectural finish including Kynar, anodized, powder coat, stainless steel, baked enamel and more. In addition to thermal improvement, Mapes-R panels can meet local building codes for sound, fire and impact resistance.

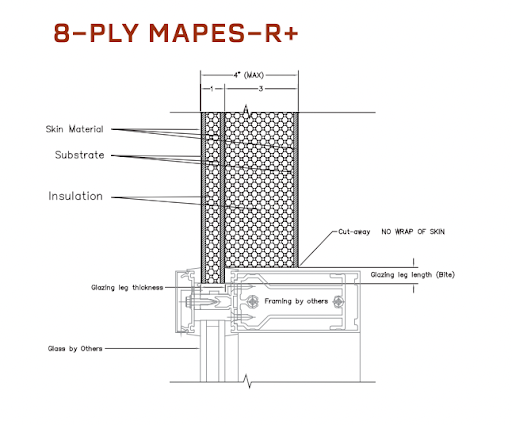

Mapes-R+ Panels

For projects where energy efficiency is an integral part of the design, Mapes-R+ panels deliver an increased R-value of up to 500% without modifying an existing frame.

Mapes-R+ panels are perfect for applications like windows, curtain walls, spandrel areas and storefronts. The rabbeted edges on the panel’s interior side allow the panel to be thicker than the glazing pocket will allow.

These panels can be up to 6 inches thick with isocyanurate insulation to achieve an approximate R-value greater than 40, and they can still be installed in a 1-inch deep glazing pocket (or other glazing pocket depth).

Other Panels

Other panels like glass and brick panels have significantly lower R-values, making them a poor choice for commercial building applications.

Standard glass panels have low thermal resistance, typically around R-1 to R-2. Similarly, brick or concrete panels have low R-values usually around R-1 to R-2.

However, they can be used with other materials, like insulation boards, to achieve better thermal resistance.

Benefits of High R-Value Panels

High R-value infill panels are a smart choice for architects and builders because they have significant advantages in energy efficiency, building performance, and cost savings. Here’s why they matter:

Enhanced Thermal Performance and Energy Cost Savings

High R-value panels provide superior insulation and reduce heat transfer through the building envelope.

By minimizing heat loss in winter and heat gain in summer, these panels reduce energy consumption. Over time, this translates to significant cost savings on heating and cooling, making them a financially sound choice for long-term building operations.

It also allows building owners to purchase a smaller HVAC system, saving on initial and long-term expenses.

Improved Building Envelope Performance

High R-value infill panels contribute to a tighter building envelope, reducing air leakage and improving moisture control. This prevents issues like condensation, mold growth and structural degradation, ensuring a more durable and low-maintenance building.

Faster Installation & Reduced Labor Costs

Prefabricated insulated infill panels streamline the construction process. Their lightweight nature makes handling easier for crew members, maintaining high structural integrity while reducing installation time and labor costs.

Design Flexibility & Aesthetic Integration

Modern high R-value panels come in a variety of finishes, sizes and configurations, allowing architects to integrate them seamlessly into different design visions without compromising performance.

Choosing the Right Insulated Panel for Your Project

When deciding on the right insulated panel for your project, there are several factors that you should consider in addition to the R-value of the panels.

Climate Considerations

The new building’s climate plays a major role in the design decisions, as certain factors can impact energy efficiency.

Temperature Extremes

Cold climates require high-R value panels with superior thermal resistance to reduce heat loss and prevent condensation within the wall assembly. Insulated metal panels (IMPs) and structural insulated panels (SIPs) are highly recommended for cold climates.

Hot climates need panels with reflective surfaces or cool roof coatings to minimize heat absorption and reduce cooling loads and energy costs.

Buildings in mixed climates require dynamic insulation solutions that balance thermal performance throughout seasonal temperature shifts.

Humidity & Moisture Control

When building in high-humidity regions, vapor barriers and moisture-resistant insulated infill panels are necessary to prevent condensation and combat mold growth. Panels with integrated air and moisture barriers can enhance long-term performance.

In dry climates, moisture control is less critical, but UV resistance and thermal stability should be prioritized to prevent material degradation.

Budget and Code Compliance

Budget is always a consideration, but that doesn’t mean that the insulated infill panels with the lowest price are the best choice.

It’s important to weigh the upfront costs with the long-term benefits of any infill panels that you’re considering. Remember to factor in the cost of transportation and the labor cost of assembling the panels on the job site.

For code compliance, check state energy and building code requirements. High-performance panels can also contribute to qualifying for LEED or net-zero energy building certifications.

How To Select The Right Infill Panels For Your Project

The experts at Mapes want to help you choose the right insulated infill panels for your project to provide the best energy efficiency.

Look through our available panels to learn more about the panels we offer and to find the right panel for your project. Or, you can check out the Mapes’ selection guide if you need guidance in choosing the most energy-efficient panels for a current or upcoming project.